Working principle and application field analysis of two-stage compressor—Shared by Sollant

Two-stage compressor is an important refrigeration equipment widely used in refrigeration, air conditioning and industrial fields. This article will describe how a two-stage compressor works and how it is used in different applications, including refrigeration, air conditioning systems, and industrial applications.

Table of Contents

First, the working principle of the two-stage compressor:

Two-stage compressors use two stages of compression to increase refrigeration performance and efficiency. Its working process can be summarized as the following steps:

First level of compression:

The low-temperature and low-pressure refrigerant gas is sucked in from the low-pressure side, and then compressed into high-temperature and high-pressure gas by the rotary action of the compressor.

cool down:

The high-temperature and high-pressure gas after the first-stage compression enters the condenser, where it exchanges heat with the cooling medium (usually air or water), cooling the gas and condensing it into a high-pressure liquid.

Expansion:

The high-pressure liquid enters the evaporator through the expansion valve (throttle valve), and the pressure drops sharply, so that the liquid evaporates into a low-temperature and low-pressure gas.

Second level of compression:

The low-temperature and low-pressure gas is sucked into the second-stage compressor again, and after being compressed, it becomes high-temperature and high-pressure gas.

Cool again:

The high-temperature and high-pressure gas enters the second condenser to exchange heat with the cooling medium, so that the gas is cooled and condensed into a high-pressure liquid.

Inflate again:

The high-pressure liquid enters the second evaporator through the expansion valve, and the pressure is reduced again, so that the liquid evaporates into a low-temperature and low-pressure gas.

With the working principle of two-stage compression, the refrigerant is compressed and expanded in two compressor stages, resulting in improved cooling and energy efficiency.

Second, the application field analysis:

Refrigeration field:

Two-stage compressors are widely used in the field of refrigeration, especially in scenarios that require high refrigeration capacity and low temperature, such as cold storage, frozen food processing, and pharmaceutical cold chains. Through the working principle of two-stage compression, lower evaporation temperature and higher refrigeration efficiency can be achieved.

Air Conditioning System:

Two-stage compressors also have important applications in air conditioning systems. In places such as large commercial buildings, office buildings, and hotels, air conditioning systems need to meet large cooling loads and indoor temperature control requirements. Two-stage compressors can provide higher cooling capacity and more stable temperature control, making the air conditioning system more efficient and reliable.

Industrial application:

Two-stage compressors are also widely used in industrial fields. For example, low-temperature refrigeration in chemical processes, industrial refrigeration equipment, freeze dryers and cooling towers, etc. Two-stage compressors can meet complex industrial needs, providing stable cooling performance and reliability.

Refrigeration equipment and facilities:

Two-stage compressors are also widely used in refrigeration equipment and facilities, such as freezers, refrigerated vehicles and refrigerated ships. These devices require efficient refrigeration systems to maintain a low temperature environment to ensure the quality and safety of goods and items.

Shipping and Logistics:

Two-stage compressors also play an important role in the transportation and logistics industry. Cold chain logistics systems require reliable refrigeration equipment to maintain the freshness and quality of goods, such as food, pharmaceuticals and chemicals. The two-stage compressor ensures that the cargo is kept at a suitable temperature throughout the transportation process by providing high-efficiency refrigeration capacity and stable temperature control.

Summarize:

Two-stage compressors improve refrigeration performance and efficiency through the working principle of two-stage compression and expansion. It finds wide application in areas such as refrigeration, air conditioning systems, industrial applications, and transport and logistics.

By providing higher cooling capacity, stable temperature control and reliable performance, two-stage compressors play an important role in various application fields. With the continuous advancement and innovation of technology, two-stage compressors will continue to develop in the future and provide more efficient and sustainable refrigeration solutions for various industries.

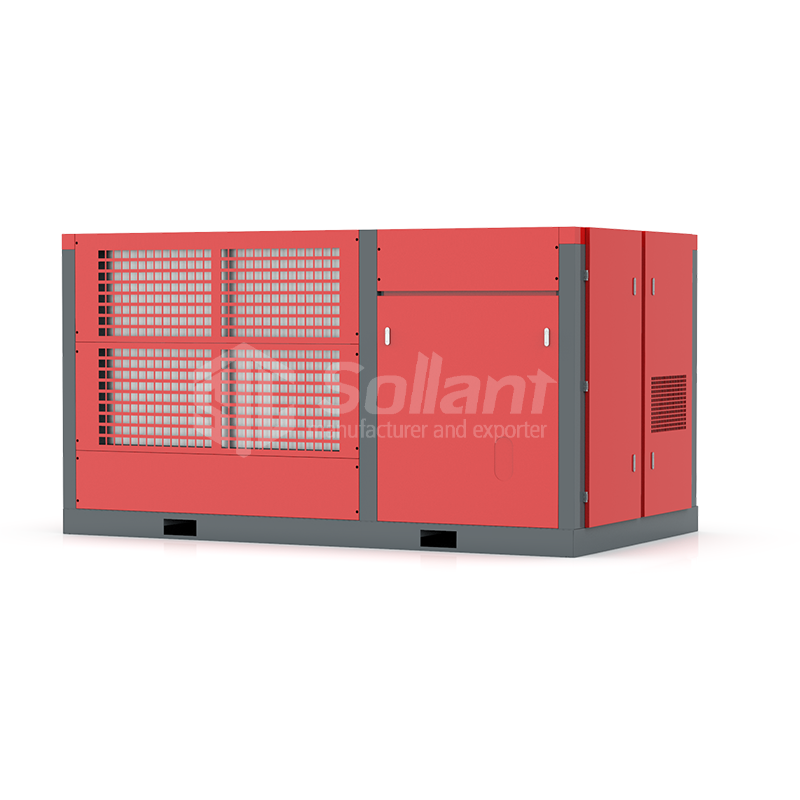

The brand “Sollant” specializes in the R&D, manufacturing, sales and after-sales of compressors, oil-free compressors and hosts, special gas compressors, various air compressors and post-processing equipment. Provide customers with high-quality, environmentally friendly and Efficient air system solutions and fast and stable technical services. Sollant Corporation is customer-centric. Customer satisfaction is the purpose of our Sollant people.

Sollant Focus on Energy Saving.